Premium grade flooring is all we can say about the wood floors manufactured by Country Flooring. With better than average lengths and superior grading standards Country Flooring is our favorite manufacturer of quality hardwood floors.

FINISHING PROCESS

All Country Flooring products are finished with 7 coats of UV cured aluminum oxide finish offering a 25 yr warranty.

MILLING

The flooring is tongue and groove on all 4 sides ensuring the best installation possible. (end matched)Minimum lengths on all products of 15” compared to the industry standard of 9” for other manufacturers makes for a faster installation as well as a more aesthetically appealing look. The edges are micro-beveled with the smallest micro bevel in the industry to protect the edges of the flooring during the installation.

The grading of Country Flooring is Simple.

Prime Grade = Clear / Select and Better - For a clean, uniform look.

Standard Grade = Select and #1 mix.(Allows for color variation, and knots) - For a natural looking floor that contains natural characteristics.

Country Grade = #1 and #2 grades, (allows color variation and knots) Will not contain open hole knots - nearly 100% usable material. Sometimes reffered to as Rustic (appearance only)

Engineered Flooring Details- Quality is the difference.....

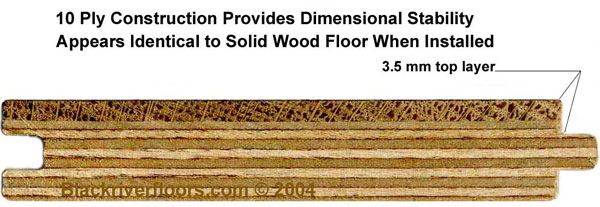

Top Quality Engineering with multiple plies (7-10) makes this engineered single strip flooring the perfect choice for glue down installations and areas of high humidity fluctuations. View a cross section below of the typical construction for Country Flooring Engineered single strip floorings.

The thick top layer is sawn and not a cheap veneer like similarly priced products. This more expensive process of using a sawn top layer combined with a multilevel base provides a top quality product that is dimensionally stable and can be refinished in the future. When this product is installed it will look identical to a solid wood flooring.

Hard Maple has a Janka hardness rating of 1450 compared to 1260 for Red Oak.

Working Properties: The wood turns well, is harder to work than softer woods, and has high nail-holding ability. It stains and polishes well, but is intermediate in gluing.

Durability: Rated as slightly or nonresistant to heartwood decay Preservation: Moderately resistant to penetration with preservatives

Uses: Lumber, distillation, veneer, crossties, paper pulp, flooring, furniture, pallets, boxes and crates, shoe lasts, handles, woodenware, novelties, spools and bobbins, bowling alleys, dance floors, piano frames, bowling pins, cutting blocks, pulpwood and turnery.

Northern Hard Maple is a dense, strong, remarkably hard and supremely durable product. Offering a wide range of uses and color possibilities, Northern Hard Maple is close-grained, hard-fibered, free from slivering and splintering, and polishes well under friction. When given a clear finish its natural beauty stands out. Because wood is a natural product, it is subject to color variations resulting from differing growing conditions. The color of maple heartwood is brownish — the sapwood is much lighter.

Hard maple has an unusual ability to resist pointed pressure without abrasion. It is easily covered with attractive finishes.

Wood flooring is quickly regaining a strong market share in the floor covering industry. More and more homeowners and commercial tenants are turning to the natural beauty of wood for aesthetic and health benefits. The Occupational Safety and Health Administration (OSHA) is currently working to regulate indoor air quality. According to their list of poor air quality sources, carpeting, among many other sources inside the home and office, contributes to poor air quality due to its makeup of alcohols, formaldehyde, 4-methylethyl-benzene, 4-phenylcyclohexene, and styrene.

Within the selection of wood floors, consumer preferences are shifting toward lighter colored woods. Northern hard maple is regarded as a premium specie among domestic hardwoods. Northern hard maple is dense, strong, remarkably hard and extremely durable. Its unique character offers a wide range of uses and a natural lighter color that complements all home furnishings from ultra contemporary to country decor. The quality of this premium hardwood begins in the northern forests above the 35th parallel where shorter growing seasons and longer winters produce a densely-grained maple with rich, consistent color and fewer imperfections.

GENERAL GUIDELINES

JOBSITE CONDITIONS

ACCLIMATION

MOISTURE REQUIREMENTS AND MOISTURE TESTING

JOBSITE CONDITIONS

Part I – Minimum Jobsite Requirements

A. Wood flooring should be one of the last jobs completed on the construction project. Limit foot traffic on finished wood flooring.

B. Evaluate the jobsite for potential problems before installation begins, and before wood flooring is delivered to the jobsite.

C. Unless a waiver or letter of protest listing exceptions exists, installation constitutes acceptance of subfloor/substrate, the jobsite itself – including the ambient temperature and relative humidity at the time of installation, and all impacting variables that may affect a wood floor.

1. Surface drainage should direct water away from the building.

2. Do not deliver wood flooring to the jobsite or install wood flooring until the building is enclosed.

3. If heating and/or air-conditioning is in operating condition, it needs to be operating. If it is not possible for the permanent heating and/or air-conditioning system to be operating before, during and after installation, a temporary heating and/or dehumidification system that mimics normal temperature and humidity conditions can enable the installation to proceed until the permanent heating and/or air-conditioning system is operating.

4. Do not deliver wood flooring to the jobsite or install wood flooring until appropriate temperature and humidity conditions have been achieved. Appropriate temperature and humidity conditions are defined as those conditions to be experienced in the building after occupancy.

5. Do not deliver wood flooring to the jobsite or install wood flooring until all concrete, masonry, plastering, drywall, texturing and painting primer coats are completed.

6. Basements and crawl spaces must be dry. If power washing is required in the basement, do so before wood flooring is installed and allow subfloor and basement to dry before installing wood flooring.

7. Crawl space should be a minimum of 18†(457mm) from ground to underside of joists.

8. Crawl space earth (or thin concrete slab) should be covered 100 percent by a vapor retarder of black polyethylene (minimum 6 mil) or any recommended puncture-resistant membrane, such as Class C, meeting ASTM D-1745. See Figure 1-1.

9. Crawl Space Conditions

9. Crawl Space Conditions

a. Where a proper ground

covering is in place and when venting is required by local building codes, the crawl space should have perimeter venting equal to a minimum of 1.5 square feet per 100 square feet of crawl space square footage, unless local building codes differ from this specification. Note: Local-building codes may differ. Follow local building codes.b. For crawl spaces without ventilation openings, vapor retarder joints must overlap a minimum of 6 inches and be sealed or taped. The vapor retarder should also extend at least 6 inches up the stem wall and be attached and sealed to the stem wall. Continuously operated mechanical exhaust and perimeter wall insulation or conditioned air supply and insulation must be provided.

10. Note the grade level so that the correct type of flooring and system can be specified for the job. Engineered and floating floors can be appropriate for above-grade, on-grade and below-grade installations. Solid wood flooring can be appropriate for above-grade and on-grade installations, but not for below-grade installations. If the soil surrounding a structure is 3 inches or more above the floor of any level, consider that level below grade. This includes walk-out basements. In addition, the surrounding soil should be sloped away from the structure. See Figure 1-2.

10. Note the grade level so that the correct type of flooring and system can be specified for the job. Engineered and floating floors can be appropriate for above-grade, on-grade and below-grade installations. Solid wood flooring can be appropriate for above-grade and on-grade installations, but not for below-grade installations. If the soil surrounding a structure is 3 inches or more above the floor of any level, consider that level below grade. This includes walk-out basements. In addition, the surrounding soil should be sloped away from the structure. See Figure 1-2.

11. Subfloors (wood or concrete) should be checked by an appropriate method for establishing moisture content. Average

subfloor moisture content should be within the range as specified for the product by the product manufacturer.12. Where the minimum jobsite conditions are present, the flooring can be delivered and stored in the rooms in which it will be installed.

Part II - Additional Jobsite Conditions for Factory-Finished Flooring

A. All finished wall coverings and painting should be completed. Note: Base and shoe mold may be installed and finished after the flooring installation.

B. After installation, if you choose to protectively cover the floor, cover the floor completely, since some species are light-sensitive and uncovered areas may change color. However, covering a glue-down application may not allow some adhesives to properly cure. Follow the flooring and adhesive manufacturer’s recommendations. Use a covering material with a vapor permeance (perm rating) of 1 perm or more (tested I accordance with ASTM E-96) to avoid trapping moisture/vapor on or within the floor. A common reinforced builder’s paper is a good choice. Any covering should be taped, using a low-adhesion tape, to base or shoe moldings. Avoid taping to finished flooring. When taping paper or sheets together, tape them to each other, not to the floor.

ACCLIMATION

ALWAYS FOLLOW THE MANUFACTURERS’ RECOMMENDATIONS REGARDING HOW AND WHETHER TO ACCLIMATE WOOD FLOORING.

Part I – General Acclimation Guidelines

(For a more detailed discussion of acclimation issues, See Appendix B.)

A. Storage and Conditions

1. Do not store wood flooring at the jobsite under uncontrolled climate conditions. Garages and exterior patios, for example, are not acceptable areas to store wood flooring.

2. Ideal interior climate conditions vary from region to region and jobsite to jobsite. It is your responsibility to know what your “ideal†climate conditions are and build your floor around those conditions. For a general view of moisture-content averages by region, refer to Appendix D and Appendix E.

B. Acclimation

Note: Some manufacturers do not require acclimation for certain products prior to installation. If the manufacturer recommends that the wood flooring be acclimated before installation, proceed as follows:

1. Ensure that the building is enclosed.

2. Verify that the building is maintained at normal living conditions for temperature and humidity.

3. Where building codes allow, permanent heating and/or air-conditioning systems should be operating at least five days preceding installation to promote proper acclimation. For radiant heat see Appendix H.

4. If it is not possible for the permanent heating and/or air-conditioning system to be operating before, during and after installation, a temporary heating and/or dehumidification system that mimics normal temperature and humidity conditions can enable the installation to proceed until the permanent heating and/or air-conditioning system is operating.

5. Upon delivery, check wood flooring moisture content with a moisture meter to establish a baseline for required acclimation. Check the moisture content of multiple boards. A good representative sample is typically 40 boards for every 1,000 square feet of flooring. Acclimate to manufacturer’s recommendations or as necessary according to geographical location and your jobsite location.

6. Prior to installation, ensure that wood flooring is within acceptable range of moisture content with the wood subfloor. For solid strip flooring (less than 3†wide), there should be no more than 4 percent moisture content difference between properly acclimated wood flooring and subflooring materials. For wide-width solid flooring (3†or wider), there should be no more than 2 percent difference in moisture content between properly acclimated wood flooring and subflooring materials.

MOISTURE TESTINGPart I - Moisture Testing for Wood Subfloors

A. Testing Requirements

1. Test for moisture at several locations in the room — a minimum of 20 per 1,000 square feet — and average the results. A high reading in one area indicates a problem that must be corrected. Pay special attention to exterior and plumbing walls

Part II - Acceptable Vapor Retarders Over Wood Subfloors

A. ALWAYS FOLLOW LOCAL CODES AND MANUFACTURERS INSTRUCTIONS FOR ACCEPTABLE VAPOR RETARDERS.

B An acceptable vapor retarder is a vapor resistant material, membrane or covering with a vapor permeance (perm rating) of greater than or equal to

.7 and less than or equal to 50 when tested in accordance with ASTM E-96 Method A. Installation of a vapor retarder reduces the potential for moisture or vapor related problems, but does not guarantee elimination of moisture or vapor related problems. Install a vapor retarder over wood panel or board sub-floors prior to installing nail down solid strip or plank flooring. Over-lap seams a minimum of 4 inches or more as required by manufacturer or specifier and local building codes.C. Some examples of acceptable vapor retarders over wood subfloors include:

1. An asphalt laminated paper meeting UU-B-790a, Grade B, Type I, Style 1a.

2. Asphalt-saturated kraft paper or #15 or #30 felt that meets ASTM Standard D-4869 or UU-B-790, Grade D.

D. NOTE:

1. A vapor retarder has some extra benefits in that it eliminates wood-on-wood contact, wood strips slide more easily when positioned, minimizes the impact of seasonal humidity change and may reduce dust and noise levels.

2. However, by today’s standards, asphalt saturated kraft or felt paper may not be an effective vapor retarder in all applications. The 2006 International Residential Code requires a vapor retarder on the warm-in-winter side of exterior floors (a floor over a vented crawl space, for example), with a vapor permeance of 1 perm or less in Zones 5 and higher.

3. Over a wood subfloor, do not use an impermeable vapor retarder material with a perm rating of .7 or less, such as 6 mil polyethylene film or other polymer materials, as it may trap moisture on or in the wood subfloor.

4. Do not use common red rosin or building paper which is not asphalt saturated. They are not vapor retarders as their perm rating is far greater than 50.

Part III - Moisture Testing for Concrete Slabs

NOTE: All tests give a result – at the time the test is done. And in general give you the ability to start or not start a job – these tests do not give a permanent condition of your substrate merely a “at the time the test was performed†indication.

A. Testing Requirements

1. Before moisture testing begins, the concrete slab must be a

MINIMUM of 30 days old.B. Qualitative Moisture Tests

1. Electrical Impedance Test and Electrical Resistance Test (Moisture Meter)

Follow meter manufacturer’s instructions.

a. Use moisture meters designed specifically for concrete moisture testing.

b. Test within the body of the slab (electrical resistance), as well as at the surface (electrical impedance).

c. These testing methods are not recognized by any standard and should not be used for the purpose of accepting or rejecting a floor. These electronic tests are useful survey tools to broadly evaluate the relative moisture conditions of a slab and to select locations for quantitative moisture tests.

d. If the moisture meters indicate the presence of excessive moisture, as per wood flooring or meter manufacturer’s recommendations, further testing is required using relative-humidity testing (ASTM F-2170), calcium chloride testing (ASTM F-1869) or calcium carbide (CM) testing (ASTM D-4944-04 and MilSpec CRD-C154-77).

2. Phenolphthalein Test

a. Perform one test per 200 square feet of surface area, with a minimum of two tests per jobsite.

b. Chip a small section of concrete off the floor and apply 3 percent phenolphthalein in alcohol solution (available at most druggists) in the area. A red color indicates that moisture is present. Always chip the concrete as this protects against the possibility that a concrete sealer was applied.

IMPORTANT: Keep phenolphthalein out of direct sunlight. The average shelf life of phenolphthalein is six months.

c. If the phenolphthalein test indicates the presence of excessive moisture, further testing is required using relative-humidity testing (ASTM F-2170), calcium chloride testing (ASTM F-1869) or calcium carbide (CM) testing (ASTM D-4944-04 and MilSpec CRD-C154-77).

C. Quantitative Moisture Tests

1. Relative Humidity Testing – ASTM F-2170 (Standard Test Method for Determining Relative Humidity in Concrete Floor Slabs Using In Situ Probes)

a. Select test locations to provide information about moisture distribution across the entire concrete floor slab. For slabs on grade and below grade, include a test location within three feet of each exterior wall.

b. Perform three tests for the first 1,000 sq ft and one test for every additional 1,000 sq ft thereafter.

c. At least 48 hours before test is placed, concrete floor slabs should be at the same temperature and humidity that is expected during service conditions.

d. Use a rotary hammer-drill to drill holes in the concrete slab; 40% depth of slab is required for the holes when concrete is drying from one side and 20% when drying from both sides.

Follow manufacturer’s instructions provided with test kits.e. Allow 72 hours to achieve moisture equilibrium within the hole before making relative humidity measurements.

f. ASTM F-710 provides installation guidelines for acceptance of hardwood flooring using relative-humidity testing. Typical limits for wood and wood-based products are 75% relative humidity. When getting readings over 75%, you must use a proper vapor retarder, based on the flooring manufacturer’s recommendations, or wait for further concrete curing.

2. Calcium Chloride Test – ASTM F-1869 (Test Method for Measuring Moisture Vapor Emission Rate of Concrete Subfloor Using Anhydrous Calcium Chloride)

a. Select test locations to provide information about moisture distribution across the entire concrete floor slab.

b. Perform three tests per 1,000 square feet of surface area. Add one additional test for each 1000 square feet thereafter.

c. At least 48 hours before test is placed, concrete floor slabs should be at the same temperature and humidity expected during service conditions

d. The actual test area shall be clean and free of all foreign substances. Use approved OSHA work practices for removal of all existing flooring materials and debris.

e. Blast or grind a minimum area of 20 inches by 20 inches and let stand for a minimum period of 24 hours prior to setting test.

f. Follow manufacturer’s instructions for properly placing tests onto concrete.

g. Tests are to be covered and left in place for 60 to 72 hours. Follow manufacturer’s instructions for labeling and recording time and date of test.

h. Send the test to a certified laboratory for results and documentation, or perform the measurements as per ASTM F-1869.

i. Always following the flooring manufacturer’s guidelines and specifications to

determine when the concrete slab is ready for installation.j. ASTM F-710 provides installation guidelines for acceptance of hardwood flooring using calcium-chloride testing. Typical limits for direct glue-down wood flooring is 3lbs/1000sf/24hr. When getting readings over 3 lbs and up to 7 lbs, you must use a vapor retarder. A reading over 7 lbs may not be acceptable for wood flooring installation. Follow the wood flooring manufacturer’s recommendations. In the case

of a glue-down installation, the adhesive manufacturer may also have recommendations.NOTE: For information on the tests listed above, contact your distributor or call NWFA at 800-422-4556 U.S. or 800-848-8824 Canada for the source nearest you.

3. Calcium Carbide (CM) Test – ASTM (modified) D-4944-04, MilSpec CRD-C154-77

a. The calcium carbide test, also known as the CM test or calcium carbide bomb, is more widely used in Europe than in the United States. It is a gas-pressure test in which moisture in the concrete reacts with calcium carbide crystals to create acetylene gas, and the gas pressure produced is measured to provide a moisture content reading, expressed as a percentage of moisture. Follow the directions provided by the test-kit manufacturer. A reading of over 2.5% requires use of a vapor retarder. A reading over 4% may not be acceptable for wood flooring installation. Follow the wood flooring manufacturer’s recommendations. In the case of a glue-down installation, the adhesive manufacturer may also have recommendations.

Part IV - Acceptable Vapor Retarders Over Concrete

A. ALWAYS FOLLOW LOCAL CODES AND MANUFACTURERS INSTRUCTIONS FOR ACCEPTABLE VAPOR RETARDERS.

B. In on-grade and below grade applications, always add a vapor retarder. Test concrete for moisture. For concrete slabs with a calcium chloride reading of greater than 3 lbs, a relative humidity reading of greater than 75%, or a calcium carbide (CM) rating of greater than 2.5%, install an impermeable vapor retarder with a perm rating of less than .15 perm.

C. The 2006 International Residential Code defines a vapor retarder as a vapor-resistant material, membrane or covering such as foil, plastic sheeting or other material recommended by the manufacturer having a permeance rating of 1 perm or less, when tested in accordance with ASTM E-96 Method A.

D. The NWFA recommends an "impermeable" vapor retarder with a perm rating of less than or equal to .15, thereby limiting the passage of moisture to near zero.

E. Some acceptable vapor retarders over concrete include:

1. A minimum 6 mil construction grade polyethylene film, with perm of .13, or other impermeable material with a perm of .15 or less is recommended. An premium polymer material meeting ASTM D-1745 for concrete with higher tensile, tear and puncture resistance is highly desirable.

2. Double felt: Two layers of #15 asphalt saturated felt paper that meets ASTM Standard D-4869, with the first layer adhered to the slab in a skim coat of appropriate adhesive, and a second layer adhered to the first layer with appropriate adhesive.

3. A chemical retarder or urethane membrane, as recommended by the adhesive or wood flooring manufacturer. These are usually in the form of a liquid-applied or trowel-applied membrane dispensed from a bucket following manufacturer recommendations.

| No Room Scenes Found. |